SUPERIOR® gyratory crushers - Automation - PDF Catalogs

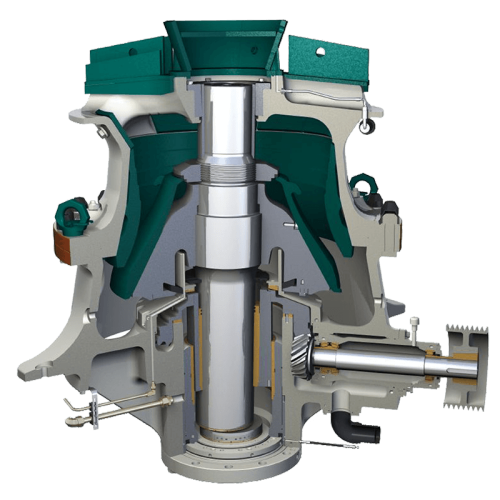

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 High-strength shell design, proven in the toughest applications, provides trouble-free operation and long life 3 Effective dust seal is equipped with an overpressure air

Learn More

sizes of gyratory crusher and capacity

Capacity Of The Gyratory Crusher dukeprospectivehealth.org. capacity of gyratory crusher and size pdf.capacity of gyratory crusher and size pdf Gyratory Crusher shape of two cones

Learn More

Crushers - All crusher types for your reduction needs

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages.

Learn More

Gyratory VS Jaw Crushers: Advantages & Disadvantages

Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

Learn More

Gyratory Crusher Sizes

Gyratory Crusher Sizes. 11 gyratory crushers can accept 810 moisture in operation but the fine content should be preferably less than 10 the crushing action in gyratory crushers is regarded as rings or helics spirals of feed down through the crusher of which a single section may be regarded as similar to the jaw crusher get price.

Learn More

Gyratory Multi-Size 17X0500-02.0706-English.pdf - Technical

Section 0 — Safety SUPERIOR MK- II Gyratory Crushers 0-5 17X0500-02.0706 Some General Safety Instructions 1. Do not remove, cover or disable any installed safety devices, guards, warning signs or tags. They are attached to equipment to warn personnel of possible danger and prevent injury. Use OEM replacements in the event any safety devices, warning signs or tags become damaged or unreadable.

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit.

Learn More

Difference Between Jaw Crusher and Gyratory Crusher

The request of input particle size of the jaw crusher is strict. After blasting, it is necessary to impact and crush the big stone to meet the requirement of

Learn More

CG810 Primary Gyratory Crusher For Maximum

It can also automatically adjust your crusher settings to compensate for crush-ing chamber wear – ensuring consistent product size. The Tank Instrument

Learn More

Gyratory Crusher Wear Plates

60 x 89; 60 x 113NT/UD. The option to customise. We provide tailored solutions for any model and size of equipment that may

Learn More

Gyratory Crusher Sizes Manufacture and Gyratory Crusher Sizes

China Gyratory Crusher Sizes Manufacture, Visit Here to Find the Gyratory Crusher Sizes That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Business Type: Manufacturer Main Markets: Africa , Americas

Learn More

PDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn More

Crushing and Screening Handbook - AusIMM

duction rate and the size and shape of the fin- closed circuit screening, final sizing and de- Both cone and gyratory crushers have an oscil-.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Key features. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h. Cyclo-palloid spiral bevel gear. Higher-capacity drive motors if required. Rugged design. Direct feed possible. High throughput rate. Optimum degree of comminution. Stroke can be changed by adjusting the eccentricity. High

Learn More

Gyratory Crusher Sizes

Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable portions of the processed material fall through the crusher at OSS and this

Learn More

Gyratory Crusher

Model Inlet size (mm) Outlet size (mm) Capacity (t/h) Power (kw) Dimensions(mm) HGT 4265 1065 140-175 2015-2875 400 3940×4170×6900 HGT 5065 1270 150-175 2400-2940 400 4460×4430×7610 HGT 5475 1370 150-200 2890-3490 450 4930×4925×8410 HGT

Learn More

Gyratory Crusher Liners - Makuri Group

Gyratory Crusher Liners Proper design of gyratory crusher liners leads to more consistent crushed product size and predictable liner change intervals. Gyratory crushers are normally the first part of the processing plant and will often have zero redundancy. An unexpected shutdown on a gyratory crusher can reduce or eliminate crushed ore

Learn More

Gyratory Crushers | Diamond Equipment Group

Diamond supplies Trio Gyratory Crushers. These crushers are a proven first stage of compression crushing for Large Mines and Quarries. Mined ore or quarried rock can processed down to a size suitable for the secondary crushers. Trio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology

Learn More

PDF) Modelling the crushing-sizing procedure of industrial gyratory crushers

2006/10/9 · Tsakalakis, K.G., 1990, Product Size Distributions of Industrial Gyratory Crushers, Mining and Metallurgical Annals, Vol. 75, pp.41-48, (in Greek with English abstract). Mineral Processing

Learn More

Gyratory Crushers - SolidsWiki

Gyratory cone crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory cone crushers can be used for primary or secondary

Learn More

Used Gyratory-crushers For Sale

UNUSED Model CG850 60 x 113 Gyratory Crusher, 800 kW (1072 HP) motor. Includes Spare Head & Mainshaft Assembly Manufacturer: Inventory ID: 3C-EG01 View Details Size 60 x 113 Model CG850

Learn More

Gyratory Crusher | Hazemag North America

GYRATORY CRUSHER | Throughput Capacity ; Crusher Size, Eccentric Throw (in.) · 4.5″, 5″, 5.5″ ; 42 - 65, 1" 1.25" 1.5", 915 1069 1234, 1031 1223 1400, 1157 1355

Learn More

What Type of Crusher Is Best for Primary Crushing?

Types of Primary Crushers · Gyratory Crushers · Jaw Crushers · Hammermills · Horizontal Shaft Impact Crushers · Sizers · Roll Crushers · Cone Crushers

Learn More

Gyratory Crusher Liners

Maximise your crushing productivity with proven Gyratory Crusher Liners. Our Gyratory Crusher Liners are focused on serving you and your operation and are tailored specifically to your needs and goals. Rely on our knowledge, engineering and technology to improve

Learn More

Gyratory Crusher-MECRU

The gyratory crusher has a huge output and is often used for coarse crushing operations of large enterprises or large production lines. It can crush the raw material ore produced by drilling and blasting to a suitable particle size for subsequent crushing process or beneficiation process. It is the key to the entire process.

Learn More

Gyratory and Cone Crusher - ScienceDirect

The Gyradisc crushers have head diameters from around 900 to 2100 mm. These crushers are always operated under choke feed conditions. The feed size is less than 50 mm and therefore the product size is usually less than 6-9 mm. 5.3. Gyratory Crusher Circuit Design, In practice, large primary gyratory crushers are seldom installed underground.

Learn More

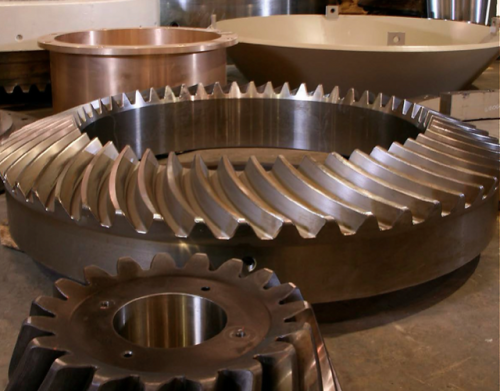

gyratory crusher | qulified cheap cnc machining milled copper-alloy casting

Gyratory Crusher Concaves - Columbia Steel Casting Co., Inc. Gyratory concaves engineered for better wear, less downtime. We use the hardest alloy that will withstand the impacts of a specific gyratory application. This depends on the compressive strength, toughness, and friability of the material being crushed. For example, crushing some tough

Learn More

Gyratory Crusher Feed Size

Maximum feed size (mm) Typical maximum product size (mm) Typical capacities (t/h) Gyratory crusher: Primary: 1500: 200-300: 1200-over 5000: Jaw crusher: Primary: 1400: 200-300: Up to 1600: Horizontal impact crusher: Primary/secondary: 1300: 200-300: Up to 1800: Cone crusher: Secondary 450 60-80Up to 1200: Cone crusher

Learn More

PDF 2. Gyratory CrushersPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn More

2. GYRATORY CRUSHERS - Metallurgist & Mineral

CRUSHING 2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co.

Learn More

Compression mining crushers | Primary crushers

Incorporate our engineering expertise into any and all of your crushing systems, no matter the size, up to and including systems for total plant. We can provide you with compression crusher parts as well as complete compression crusher machine units, such as gyratory crushers, jaw crushers and cone crushers.

Learn More