What Are the Differences Between 7 Types of Crushers?

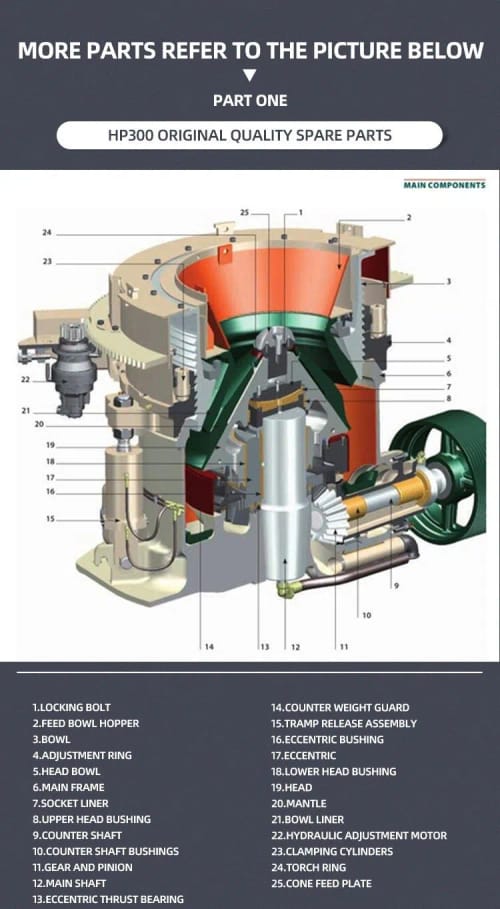

For gyratory crusher, the outer circle represents the stationary bowl covered by the concave and the inner

Learn More

Cone Crusher VS Gyratory Crusher - JXSC Mine - JXSC Rock Crusher

The cone crusher has 2.5 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly. Therefore, it is advantageous to the ore crushing, the crushing efficiency is high. 2. Different applications. In large quarries, gyratory crushers are often used as primary crushers.

Learn More

Selecting the Right Crushing Equipment | Agg-Net

Cone and gyratory crushers are both gyrating-shaft machines. They have a main shaft that gyrates and provides the crushing motion. Crushing takes place between

Learn More

How to distinguish between Cone Crusher and Gyratory Crusher?

Nov 24, · Gyratory crushers generally use dry dust-proof devices, while cone crushers usually use water-sealed dust-proof devices.

Learn More

What is a Gyratory Crusher | Quarrying & Aggregates

The structure of the gyratory crusher is the same as that of the single-cylinder hydraulic cone crusher. It is difficult to repair and maintain, and the repair cost and the cost of wear parts are high. The high fuselage of the gyratory crusher results in high infrastructure costs such as foundations and workshops.

Learn More

cone crushers vs gyratory crushershtml price

Jan 15 · Cone crusher looks like gyratory crusher but without a steep crushing chamber Just like jaw crusher it is also a compression type crusher whose reduction ratio is 41 to 61 When cone crusher works it uses the force between moveable mantle and stationary bowl liner to crush material. Zhengzhou, Henan, China.

Learn More

Choosing the Right Rock Crushing Equipment - Amcast

A cone crusher is similar to a gyratory crusher because it operates using a mantle that rotates within a bowl, but it has less steepness in the

Learn More

The difference between a gyratory crusher and a

The jaw crusher is an intermittent crushing operation, so the productivity is relatively low, impact vibration, energy consumption will be

Learn More

Gyratory Crusher Explained - saVRee

gyratory crushers or ; jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ' ; Primary Crusher'.

Learn More

What Type of Crusher Is Best for Primary Crushing?

Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry

Learn More

Should I Choose an Impact Rock Crusher or Cone Crusher? - Sepro Aggregates

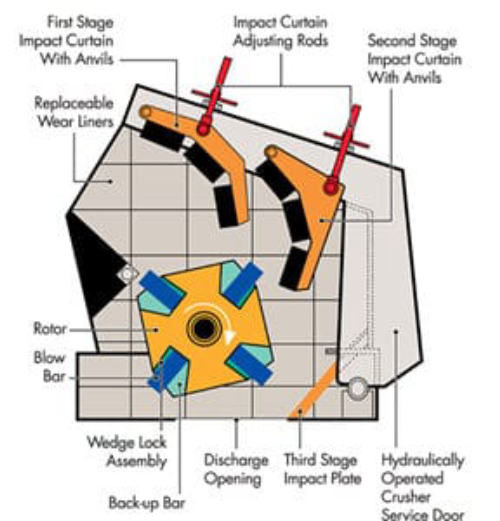

Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material colliding within the crusher.

Learn More

what is the difference between a gyratory crusher and a cone

Crusher.A crusher is a machine designed to reduce large rocks into smaller rocks,gravel,or rock dust.A cone crusher is similar in operation to a gyratory

Learn More

China Cone Crusher Vs Gyratory Crusher Manufacturers and

We aim at the achievement of a richer mind and body plus the living for Cone Crusher Vs Gyratory Crusher, Qh331 Cone Crusher, Kpi&Jci Cone Crusher, Jw55 Swing Jaw,Hammer Crusher Wood. As an expert specialized in this field, we are committed to solving any problem of high temperature protection for users. The product will supply to all over the

Learn More

keuntungan agregat vsi crusher

crusher agregat vsi atau kerucut Dapatkan Harga Jaw Crusher Kelebihan mbmttc CS Cone Crusher CS Cone Crus her is a kelemahan jaw. cone crusher crusher dampak vs Vsi Crusher Kerucut Vs stockash Kerucut Crusher menjual harga Dampak VSI crusher kerucut vs keuntungan dari crusher gyratory 171 coal russian Kutipan khusus keuntungan .

Learn More

cone crusher vs gyratory crusher - Crusher production line of

Aug 03, · In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate.

Learn More

Principle of a cone or gyratory crusher. - ResearchGate

is no significant difference between cone and gyratory crushers. In both types, the crushing action is achieved by an eccentric gyratory movement of the

Learn More

Top Service Gyratory Crusher TSUV

The lowest cost per tonne of product processed Crushing just got harder. With low grade ore deposits requiring higher power and higher throughputs than ever

Learn More

Everything You Need to Know About Rock Crushers

Cone crushers can accept medium-hard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at

Learn More

Crushing technology - kleemann

In contrast to the cone crusher, which has a fixed shaft on which the power supply unit and the head rotate, the gyratory crusher has a main shaft that can be

Learn More

Difference between Cone & Gyratory Crusher

Jan 28, · Gyratory crushers are for primary crushing. Normally used for Crushing crushing minerals as mined. The size of crusher bowl will match size of boulders. Cone crushers are used for secondary or tertiary crushing for making a cubical product for feeding to process equipment. vinayak sathe 15, Rangavi Estate, Dabolim Airport 403801, Goa, India

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Rule 2: For low capacity applications, use jaw crusher and hydraulic hammer for oversize. Rule 4: For very high capacities, use gyratory crusher.

Learn More

Buyer's Guide: Crushers - Equipment & Contracting

A gyratory crusher has a mantle that rotates within a concave bowl. Gyratory crushers and cone crushers are quite similar. A gyratory crusher has a higher

Learn More

Difference Of Gyratory Crusher And Cone Crusher-HN Mining

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory Cone Crusher are designated in size either by the gape and . Chapter 5. Gyratory and Cone Crusher 2fishygirl on Scribd . 5.2 A conveyor belt fed a Run-of-Mine iron ore to a gyratory crusher, which had a gape of 356 cm.

Learn More

gyratory crusher vs cone crusher -- VolPort

Jaw Crusher Vs Cone Crusher Which One To Choose. A cone crusher works in a similar way to a gyratory crusher, but in a cone crusher, the slope of the crushing space is not as steep. Although the cone crusher is well known for its ability to crush hard and abrasive ores and rocks, it is better suited for secondary crushing.

Learn More

Types of Crushers: What You Need to Know - Machinery Partner

Cone Crushers: A very similar concept to a gyratory crusher, however, cone crushers are not as steeply inclined inside their crushing cones. Cone crushers are

Learn More

between gyratory crusher and a cone crusher

4 24 Crusher Grinder Novamining Novamining Hence vibrating screens are deployed in between different stages of the crushers The essential difference is

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

Gyratory Crusher VS Cone Crusher. 1. The two cone shapes of the gyratory crusher are steeply inclined. The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase the need for feeding ore. Nevertheless, cone crusher has two cone shapes, which are gently inclined, vertical frustum cone. There is a

Learn More

Gyratory and Cone Crusher - ScienceDirect

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other. The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles.

Learn More

jaw crusher,gyratory crusher vs cone crusher in mining plant

Dec 30, · Firstly in Gyratory crusher the outside crushing surface flares in from top to bottom but in Cone crusher it is vice versa. Hence area of discharge gets increased Secondly,upper crushing surface can be lifted in cone crusher but not in gyratory crusher. Cone crusher can intake finer as well as coarser feeds.

Learn More

Crusher Gyratory Bijih In Vietnam

gyratory crusher crushing capacity in Vietnam. The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44) A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 44(a) ) and it is the most widely used in primary crushing stages ( Behera et al

Learn More

Gyratory Versus Cone Crusher-HN Mining Machinery Manufacturer

Gyratory Crusher vs Cone Crusher: The working principle of cone crusher is basically the same as that of gyratory crusher, but the two machines differ in some structural features .The main differences are the following aspects: 1. The shape of their crushing chamber is different. In order to meet the requirements of the feeding size, the two

Learn More