Rubber Mill Liners | AG SAG Ball Mill Liners | GTEK MINING

① Lower Cost: Our rubber mill liners are relatively cost effective as "cost per ton of ore grind" is lower;. ② Longer Life: Our rubber mill linings have "longer operational life";. ③ Less Maintenance: Rubber mill liners are engineered to resist abrasion, increasing the maintenance interval;. ④ Faster/ Safer: Rubber mill components are lighter in weight and easier to handle when changing;

Learn More

Polycorp - Rubber Liners

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world. Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26

Learn More

Rubber Mill Liners - Wear Parts For Industry | Qiming Casting

Polyurethane rubber mill liners’s working life 5-10 times than normal metal mill liners in some work conditions; Polyurethane rubber mill liners weight less than metal mill liners, which easy

Learn More

Mill liners - Outotec

We pioneered the use of rubber linings and invented Poly-Met, Megaliner and Orebed mill linings. New products are constantly being developed to enhance our customers’ ever more advancing

Learn More

Mill liner solutions

Incorporating a range of materials — including rubber, cast steel and composite options — mill liners offer industry leading wear protection.

Learn More

Ball mill liner | Magotteaux

The mill lining system is in place for two reasons. The first one is to preserve the mill shell from deterioration caused by wearing down against the mill charge. The second reason is for lifting and turning the mill contents so that they will grind. Before you choose a mill liner design, you'll want to mull over your options carefully.

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn More

Ball Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

The Lining Plate Of Ball Mill Is Gradually Replaced By Rubber And Polyurethane Lining Plate In China, But With The Continuous Application Of Rubber Polyurethane Lining Plate In The Lining Plate Of Ball Mill, It Has Gradually Replaced Manganese Steel And Other Lining Plates And Become The Mainstream Of Market Development.

Learn More

Ball Mill Rubber Liner - IndiaMART

SAKAR's ball mill rubber liners are pressure moulded to ensure highest density and engineered for maximum abrasion resistance.

Learn More

PDF WHAT MAKES US - Growth SteelPDF

significantly from mill to mill. Growth Rubber has one of the best-equipped laboratory for testing and developing differentiated rubber compounds to suit your specific operation requirements. In conventional Mill Lining Systems, Growth Rubber offers a full range of rubber liners for • SAG Mills • AG Mills • Primary & Secondary Ball Mills

Learn More

60 Duro Mill shell & liner backing rubber | Mill Backing - Reglin Rubber

AVAILABLE SIZES. Mill Backing Lining Rubber can also be supplied in cut lengths, strips, pads and a wide variety of custom cut shapes and gaskets to suit your application requirements. PART NUMBER. DESCRIPTION. WEIGHT (PER L/M) MB061200. Mill Backing Rubber With Buffed Back 6mm x 1200mm (10 L/M Rolls) 9.7 kgs. Product Information Sheet.

Learn More

Compare the Benefits of Steel VS Rubber/Poly-Met Mill Liners | When is

Let's compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball increases the cost benefit of using steel only mill liners. Looking at this chart, any time

Learn More

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

Alloy steel mill liner is wear-resistant and impact-resistant. Alloy steel has good physical and chemical properties due to its alloy properties, and its service life is more than twice that of high-manganese steel. The ball mill rubber liner has a high wear resistance index, high rebound rate, and high abrasion resistance and tear strength.

Learn More

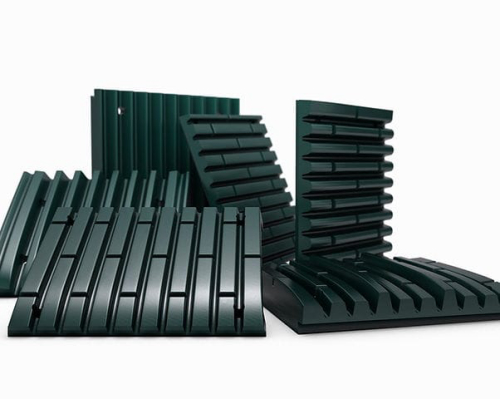

Ball Mill Rubber Liner ( SAG Mill , AG Mill

Length :1500MM. Width :100MM. Thickness :100MM. Liner :Rubber. Product description: INQUIRY. Ball Mill Rubber Liner ( SAG Mill , AG Mill ) Produced By Hebei Fengmang Technology Co.,Ltd Is Widely Used In Mining, Conveying Of Non-Ferrous Metals And Ferrous Metals, Tailings Engineering, And Providing Wear-Resistant Rubber Parts For Coal

Learn More

Rubber Ball Mill Liner | Vostosun - Mineral Processing

The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation. The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process. Gallery

Learn More

Rubber Liners Factory | China Rubber Liners Manufacturers and

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Learn More

Rubber-Metal Composite Mill Liners | Mill Wear Parts | GTEK

GTEK™ Rubber-Metal Composite Mill Liners are 35%-45% lighter than the metallic linings of the same specification. This makes it possible to design the liners composed of larger and fewer components, leading to faster and safer liner replacements, minimizing downtime and increasing mine profits. Composite liners resist pegging and peening:

Learn More

Rubber mill liners Factory | China Rubber mill liners Manufacturers

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner.

Learn More

Ball Mill rubber Liner

Most of all type of Ball Mill Liner are always used to protect the inner shell of the cylinder from being impacted and worn directly by material and

Learn More

Ball Mill Linings | Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency. Our Ball Mill Lining designs are manufactured with rubber or rubber composite materials to meet your specific requirements. Light to medium sized Steel Liners is also available for additional

Learn More

Rubber Liners - Polycorp

Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26 feet in diameter. We have supplied Rubber Liners for more

Learn More

Ball mill rubber liners | Rubber liner Manufacturer in india | Mill

Kedar rubber is one of the leading Manufacturer and exporter of Rubber liner and mill rubber liners in Ahmedabad, Gujarat and India.

Learn More

60 Duro Mill shell & liner backing rubber

Mill Backing Lining Rubber has been designed primarily for use as a wear and corrosion protection lining system. It is designed specifically to be used as

Learn More

Rubber Mill Liners Market Size 2022 Research Findings, Market Growth

In the forecast period of 2022-2026, the global "Rubber Mill Liners Market" is expected to grow at a steady rate, according to an Rubber Mill Liners Market report, which summarizes the key aspects of the market, as well as the leading key players, leading regions, and key applications. The report focuses on both qualitative and quantitative aspects of the market growth over 2022-2026.

Learn More

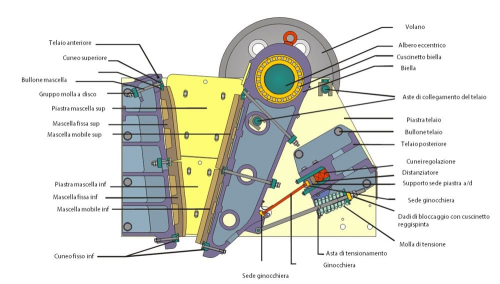

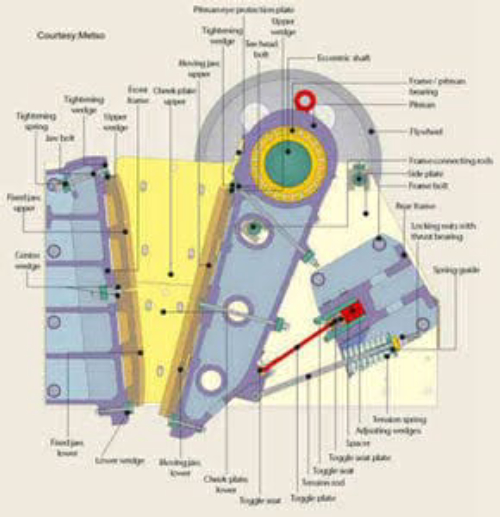

Mill Liners Filterui ImagesizeLarge

Mill Liners Filterui ImagesizeLarge 2018-07-06T21:07:30+00:00. камнедробилка гравийная . камнедробилка гравийная . щековая дробилка для продажи jan . щековая дробилка для продажи jan .

Learn More

China Rubber Liner,Cement Ball Mill Liner Plate,Abrasion Resistant

Wear Resistant Ball Mill Rubber Shell Plate. Min.Order. Unit Price. 50 Kilogram. USD 1.9 / Kilogram. Rubber Liner is mainly used in AG Mill, SAG Mill, Ball mill, Bar mill and other grinding equipment for mining, cement, chemical industry, building materials, metallurgy and other fields. The advantages of Abrasion Resistant Rubber Liners are as

Learn More

Flexible Rubber Liner Manufacturer,Mill

KEDAR RUBBER PRODUCTS, We are finest Manufacturer,Supplier and Exporter of Flexible Rubber Liner and Mill Liner Plate from Ahmedabad, Gujarat, India.

Learn More

Home [ballmillrubberliner.com

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grind-ball. At the same time we can use different forms of the shell liners Read More, HEAD LINERS (TRIANGLE)

Learn More

Polycorp - Ball Mill Liners

These liners are custom designed for your mills. Mining Ball Mill Liners PolyStl™ Liners PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded Rubber which are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger. Learn more PolyBlok™ Liners

Learn More

Ball Mill rubber Liner| Ball Mill Rubber Lining

While SAKAR's Rubber Mill Liners can well resistant the corrosion of acid and alkalis material, water, or other solutions under a certain temperature of 90 C-100 C. Reduced Weight & Lower Costs. Our Rubber Mill Liners are 75 to 80% lighter than steel liners, it increasing the energy efficiency of the ball mill by 15%. Less stress on the mill

Learn More

Grinding Mill Liners - Mineral Processing & Metallurgy

Rubber liners absorb the impact of the larger grinding media and thus protecting - the mill structure and prolonging it's life. Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure and also reduces the basic power draw.

Learn More